Vortex rocket engine

Words and graphics created by me for BBC Focus magazine's now seemly defunct online science news.

In a spin: the Dyson engine

We're used to seeing transparent vortex chambers in vacuum cleaners, but what about in a liquid rocket engine? Orbitec of Madison Wisconsin are doing for rocket engines what Dyson did for vacuum cleaners.

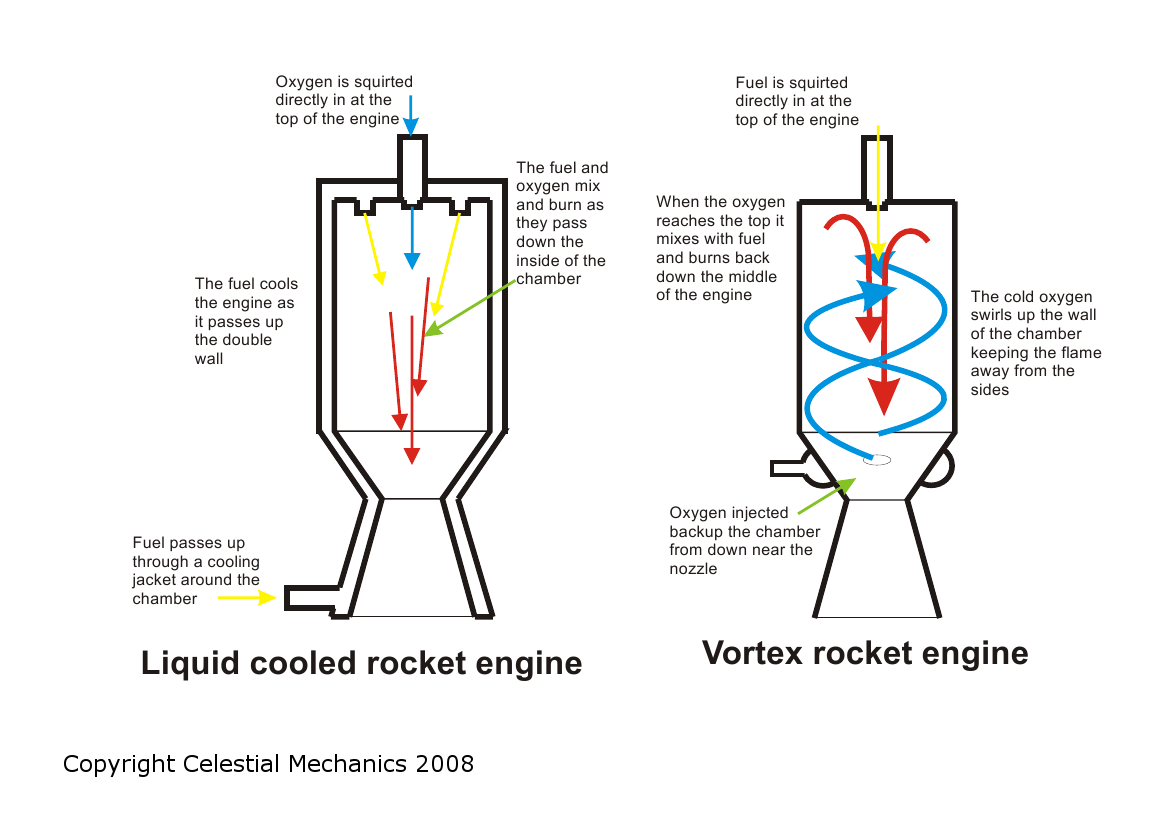

In a traditional liquid rocket engine the combustion chamber is cooled by passing fuel through a double wall around the engine. This works well, and reclaims lost energy, but is difficult and expensive to build.

In Orbitec's new engine the oxygen is sprayed back up the engine from near the exit of the chamber. This forms a vortex of cold oxygen spiralling up the inside walls of the engine. Fuel is injected normally at the top of the engine and mixes

with the oxidiser to form a second burning vortex within the first. As the hot gases flow down the engine the denser cold vortex keeps them in the middle, protecting the walls from direct heat. This means

engines could be built without the double wall, making them simpler, lighter and cheaper, the vortex also mixes the propellants better.

Orbitec's test engine demonstrated a wall temperature of only 60 celcius while containing 3000 degree combustion in the central vortex. Such a dramatic temperature difference enabled the engine to be built with a 25mm thick perspex

wall; surely the first time anyone as been able to view the inside of a running liquid rocket engine. Orbitec are now working on a prototype flight engine under a USAF contract.