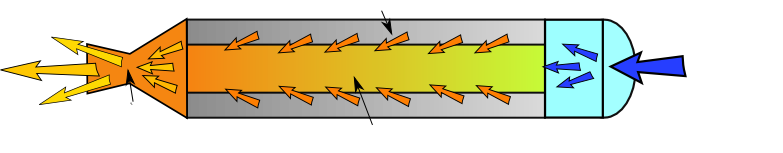

Isaac1 fuel characterisation engine

In order to design a hybrid rocket engine you first need to measure the way your chosen propellants interact, specifically the rate at which the face of the solid fuel burns back relative to the amount of

oxidiser flowing per cross sectional area of the port. When I started on the project that would become Isaac 2 at Starchaser we settled on liquid oxygen and polybutadiene rubber as propellants.

These were the most well documented hybrid propellants in the restricted literature (at least compared to the information available about solid and bi-liquid rockets), which gave us some initial data to

start a design. But we still needed to measure the behaviour of our particular fuel, and see how applicable the initial data was. As a result I designed Isaac 1 as a 100th scale version of that intended for Isaac 2, with a target thrust of 123 Newtons

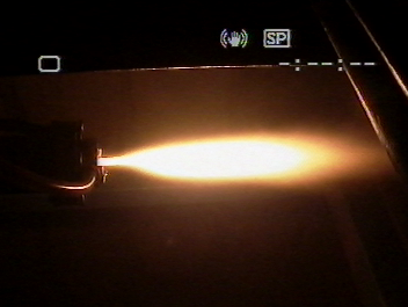

In practice because it was running directly from a high pressure LOX dewar, through a relatively small supply pipe, it never received the correct LOX mass flow and so never achieved full thrust.

It did however produce good data from a large number of test runs; this data was successfully used to design the Isaac 2 engine. The quality of the data was demonstrated by the Isaac 2's close proximity

to its design thrust, at least before other issues cut the run short.