Salford University MSc research engine

In 2000 I was able to continue my undergraduate final year project on into an MSc by research at Salford University. the objective was to assess the quality of the literature available and create a predictable,

functioning engine. This engine was originally intended as a nitrous oxide and Perspex test engine to built and flown in the Summer before the MSc, in the end it became the test engine for the entire project.

When designing a hybrid you need to know how fast the inside surface of the fuel burns in relation to the mass flow per area of oxidiser passing down the port; and how that burn rate changes as the port gets bigger

and the oxidiser is spread over a larger area. This is a very complex physical process and it is established practice to measure the behaviour of a chosen fuel and oxidiser combination to obtain two factors that will help you design other engines with those propellants.

The regression rate of the fuel is

r = aGoxn

Where r is the regression rate of the fuel face (m/s or mm/s), Gox is the Mass flux (kg/s/m2) and a and n are the fudge factors that absorb all the variables intrinsic in the process and help you design other engines!

Coming out of my undergraduate project with a still limited idea of how to design hybrids I used the values for a and n for LOX/HTPB from the rocketeer's bible, Rocket Propulsion Elements by G.P.Sutton.

This combination is nothing like nitrous and Perspex! However, while I have never done the maths, subsequent experience with the nitrous oxidised Brainiac project leads me to

believe it might actually, by shear chance, have been about the right shape. Though I'm sure with that stocky fuel block there'd have been masses of Perspex left over.

In the event it wasn't made fast enough and I didn't have the experience to really make it work at that stage, so it became the test engine for the MSc. Or Mphil, the title seemed to change between documents...

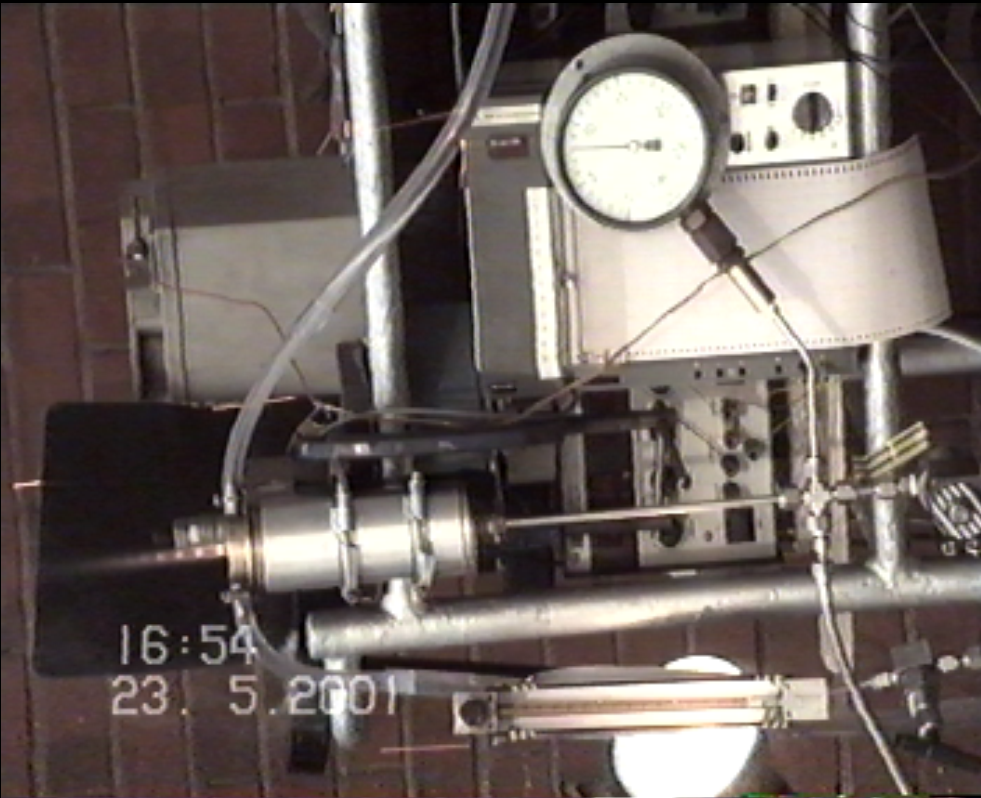

For the MSc research the plan was to run ground tests at the university using gaseous oxygen and perspex, the available regulator fixed the operating pressure at 20 bar, half what it was designed for.

Given the difference in density and supply rate the engine wasn't getting anywhere near the amount of oxidiser it was designed for. This meant the nozzle was far too large and the first tests just made pretty blue flames...

The first nozzle was made of steel, for lack of experience, it had easily

coped with the unpressurised flow and therefore the second was also

made in steel. It didn't last out one run before it became a

spectacular Roman Candle.

Fortunately around this time I received some advice from a couple of researchers at SSTL. They told me how they were using a water cooled copper nozzle for a small test hybrid and it was showing no signs of wear at

all. Because copper has a much better thermal conductivity than steel it can quickly redistribute heat away from the nozzle, and therefore also into any available coolant. A new copper nozzle with water jacket was made in

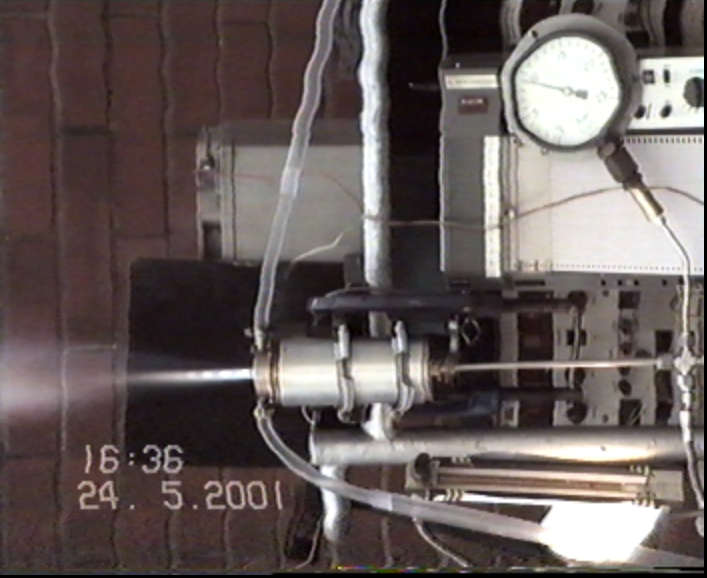

the university and has lasted for the motor ever since. It finally made the engine function as rocket chamber rather than simply a very elaborate way of burning plastic, as nicely demonstrated by the appearance of Mach

diamonds and consistent thrust.

Finally I could make a number of runs, collect data and try other fuels. I realised that with the low oxidiser flow and short Perspex port that the engine was running very oxygen rich. As demonstrated by

the almost transparent flame and white mach diamonds. In an effort to increase the fuel flow I tried wax and I was also interested in the work FAR, a now seemingly defunct group of German amateurs, were

doing with reclaimed polybutadiene from car tyres. I created a number of parrafin wax, and rubber bound with wax, fuel blocks.

Testing was done in the university yard (the Maxwell Building Well for any Salfordians), after 17.00 so as to minimise disturbance and when you could only access the yard from one direction. It was a temperate

day in May when after a number of Perspex runs I came to test the wax grain. Following the established technique it was lit with steel wool on a low trickle of oxygen, the diffusion flame was much bigger

than with Perspex. I then opened the solenoid to release the full oxygen flow...

It may have increased in memory but the noise was about three times the level of the previous tests, and of a deeper note. I stopped it straight away as we had succeeded in disturbing several meetings, tutorials and an exam

in the surrounding buildings. It also generated about three time the thrust and a visit from the safety officer, not actually a bad thing as he was very helpful, who suggested that maybe the testing had outgrown the present location.

Fortunately it was just at the time when Starchaser were able to offer a rather more remote testing area and the actual series of data collecting runs on Perspex and polybutadiene/wax was completed much more quickly at that site.

Interestingly I have never had a smooth run with wax since; I don't know if it was by chance a hotter melt grade or if the upwards firing position allowed molten wax to recirculate, but every subsequent attempt to use it has melted

in bulk and sprayed molten wax accompanied with some most unpleasant buzzing sounds.

It is my most used engine, is still in a functional condition and I hope will prove useful again in future, though I don't think I'd risk trying to fly it now!